EXPANDED FOR MECHANICS AND SEALS

DIE CUTTING

Die-cutting is an essential manufacturing technique in the packaging industry and beyond, used to create precise, custom cuts in various materials such as paper, cardboard, leather, plastic and fabrics. This method allows for the creation of complex, detailed shapes, essential for products that require unique and functional packaging. Due to its precision and versatility, die-cutting plays a crucial role in modern industry, contributing significantly to the aesthetics and practicality of finished products.

We can make on the materials, allow us to make a wide range of products

OUR WORKS

AUTOMATIC

The latest generation of automatic die-cutting machines represent a revolution in the industrial production sector. With their ability to work quickly and accurately, they allow companies to significantly increase production without sacrificing quality. The nesting system, in particular, optimizes the use of materials by reducing waste, a significant advantage from both an economic and environmental point of view. These advanced machines are the key to remaining competitive in an increasingly demanding market.

WASHERS

Washers are essential components in many mechanical applications, providing uniform load distribution and preventing surface damage. The production of washers requires advanced technology and careful design to ensure they meet the required technical specifications. With specialized eccentric presses, both standard and custom washers can be produced, adapting to different technical requirements and quantities, both in small and large series. This flexibility in production ensures that customers receive high-quality components suited to their specific applications.

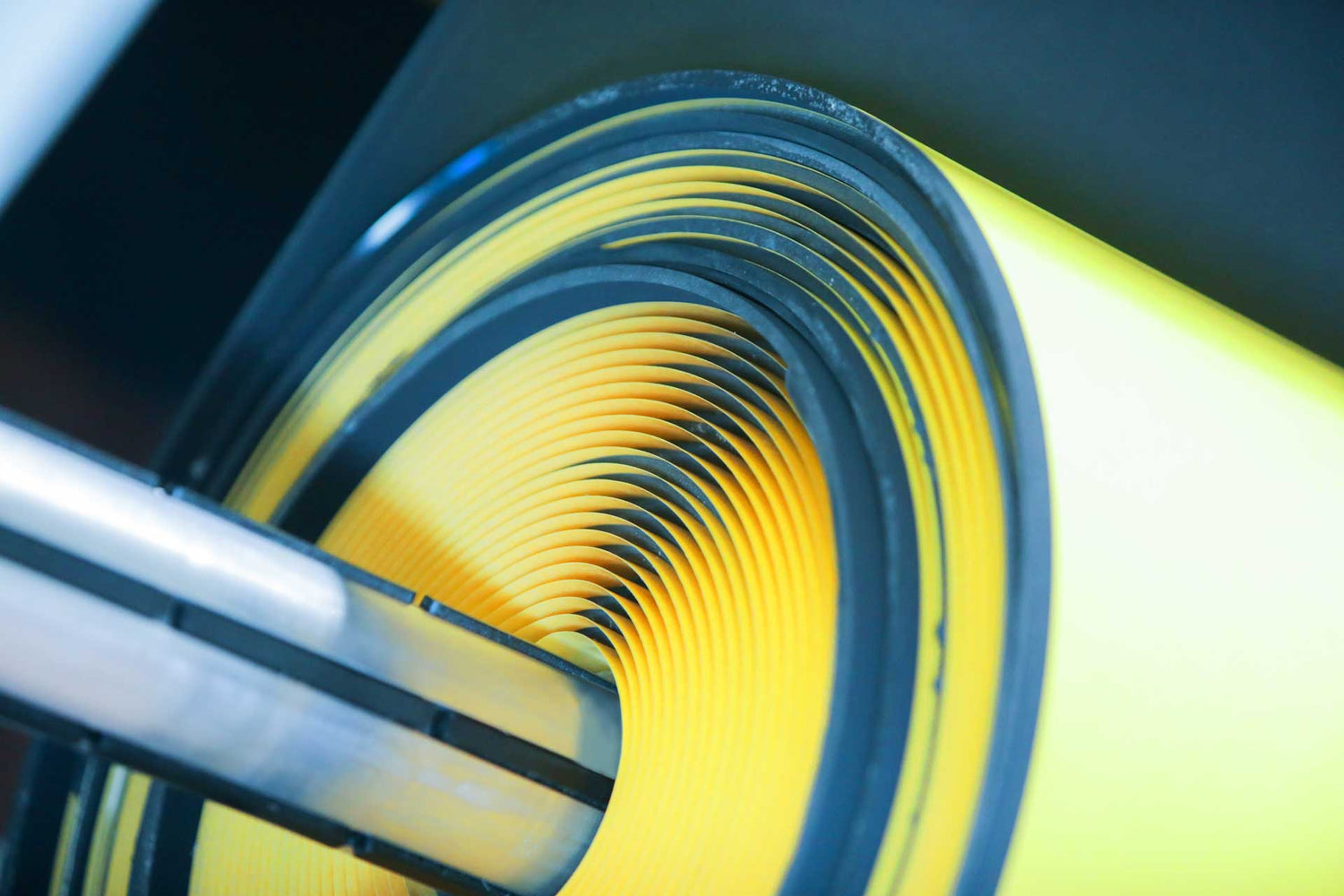

HALF CUT

The processing of adhesive gaskets to design represents a technologically advanced solution to meet specific needs in various industrial sectors. This process allows the production of customized gaskets that perfectly fit the applications for which they were designed, ensuring rapid and precise installation. The use of stamping presses and computerized drawings ensures that each gasket is cut with millimeter precision, offering a final product that meets expectations of quality and performance.

CONTINUOUS CUTTING SYSTEM

The continuous cutting system is a blade cutting system that does not require a die. The pneumatically operated oscillating blade cutting head is a tool suitable for cutting both soft and medium-hard materials, both compact and expanded. Its versatility is ideal for meeting the needs of a wide range of processes and ensuring the ability to cut, perforate and punch a large variety of materials, satisfying the changing demands of customers, for prototyping, for small and large series.

ADHESIVE

The tacking process is fundamental in many industrial sectors, allowing to make adhesive materials of various nature. Using a calender, different types of adhesives are applied on flexible, compact or expanded materials. This technique is crucial to ensure effective adhesion in products such as gaskets, tapes and labels, improving ease of application and durability over time.

PRINTED TECHNICAL ARTICLES

The broad range of industrial engineering products you offer seems to cover a wide spectrum of applications, providing essential solutions for a variety of industries. From molded rubber parts to anti-vibration elements, each component plays a vital role in ensuring the optimal operation of machinery and systems. Your ability to meet the specific needs of industries such as metalworking, appliance and automotive demonstrates a commitment to quality and innovation. This versatility is crucial to maintaining competitiveness in today's industrial marketplace.

COMPACT PLASTICS

Semi-finished products in polymeric materials represent a versatile and reliable solution for many industrial applications. Thanks to their resistance to corrosion and excellent mechanical properties, these materials are ideal for the production of components for demanding sectors such as the metalworking, petrochemical and aeronautical ones. The possibility of transforming sheets and rods into custom gaskets through mechanical processing or die-cutting allows for extensive customization of the final product, adapting perfectly to the specific needs of each use.

FIBERS, PAPER AND SEALS

Different types of fibres are also used in the production of our product range.

The vulcanized fiber,

comes from pure cotton cellulose, suitable for various applications and fields, it is used as an insulator for slots on electric motors, for mechanical and insulating supports, self-lubricating slide guides, silent gears and for explosive or flammable environments. Very stable from a dimensional point of view, the vulcanized fiber is not attacked by oil, grease and acids, being a hygroscopic material, therefore deformable in water.

Fibres also include a range of products commonly known as asbestos-free, including aramid fibres bonded with NBR rubber, cellulose fibres bonded with SBR or NBR rubber, and carbon and graphite fibres bonded with NBR rubber.

The distinction between the three materials described above is determined by the different heat resistance, operating pressure and contact substances. They are usually indicated for air, water, solvents, steam, organic and inorganic chemicals, refrigerants and gases.

STICKERS

Double-sided positioning tapes are essential tools in many production processes and can be classified into different types depending on the support material and specific use. Transfer double-sided tape is ideal for irregular surfaces thanks to its excellent quality-price ratio. Retinati and TNT tapes, both supported, are designed to reduce the elongation of the material during positioning. PET double-sided tape stands out for its ability to prevent the migration of plasticizers, maintaining the integrity of the adhesion. Furthermore, innovation in the sector allows the application of acrylic and heat-activated foams for specific production needs.